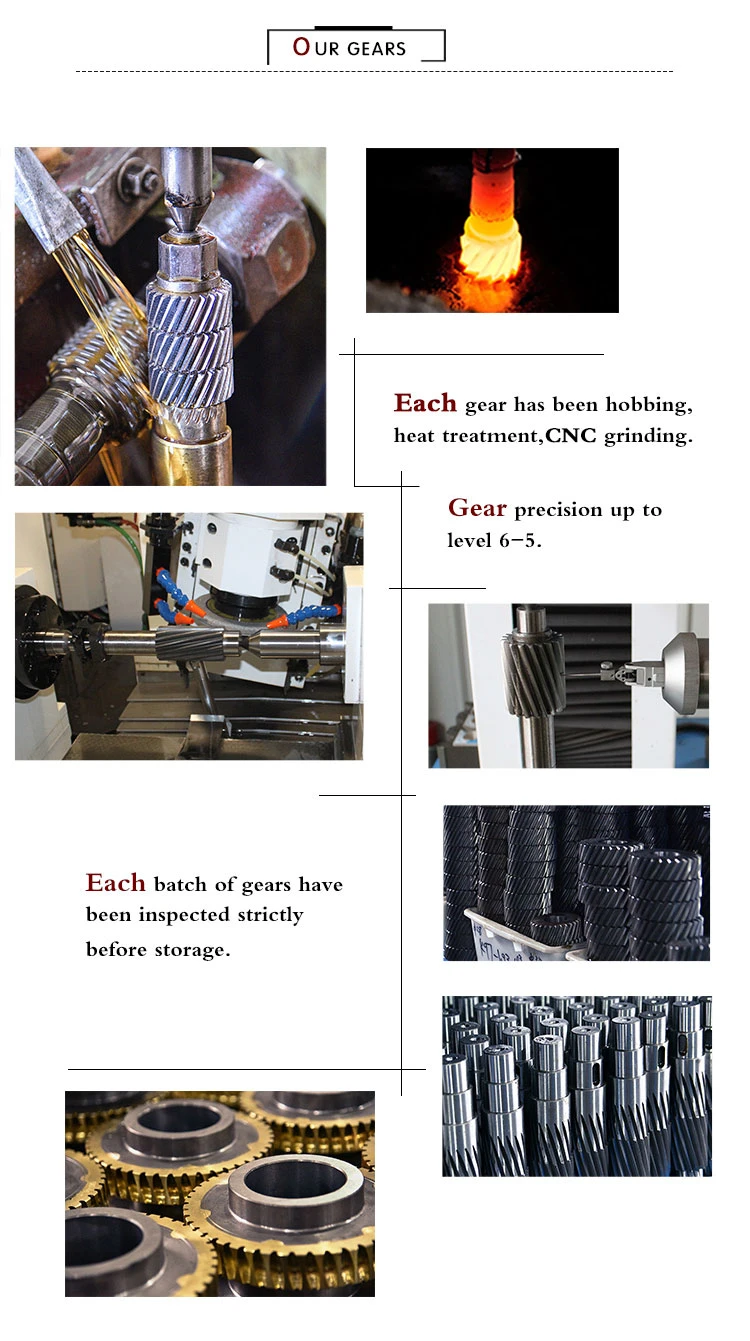

1, The gear is made of high-strength low-carbon alloy steel by carburizing and quenching. The hardness of

the tooth surface is up to HRC58-62. The gears are groun d grinding technology with high precision and

good contact.

2, High transmission efficiency: single stage is greater than 96.5%, double level is greater than 93%, third

level is greater than 90%.

3, Smooth operation and low noise.

4, Small size, light weight, long service life and high carrying capacity.

5, Easy to disassemble and easy to install.

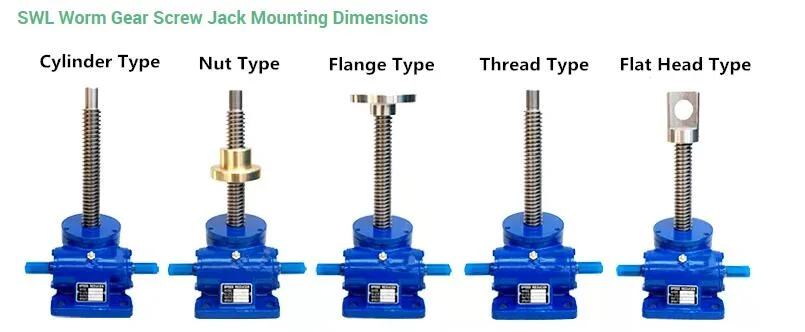

SWL 2.5 M-1 A-II-500 FZ | |||||||

SWL | 2.5 | M | 1 | A | II | 500 | FZ |

worm gear screw jack | bearing capacity(25kN) | Ratio Code | structural form code | structure | assembly form | Screw stroke(mm) | Protection form code |

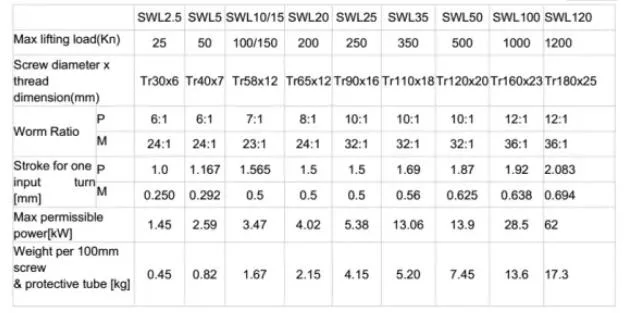

| SWL2.5 | SWL5 | SWL10/15 | SWL20 | SWL25 | SWL35 | SWL50 | SWL100 | SWL120 |

Max lifting load | 25 | 50 | 100/150 | 200 | 250 | 350 | 500 | 1000 | 1200 |

Screw diameter x pitch[mm] | Tr30x6 | Tr40x7 | Tr58x12 | Tr65x12 | Tr90x16 | Tr110x18 | Tr120x20 | Tr160x23 | Tr180x25 |

Worm Ratio | 6:1 | 6:1 | 7:1 | 8:1 | 10:1 | 10:1 | 10:1 | 12:1 | 12:1 |

24:1 | 24:1 | 23:1 | 24:1 | 32:1 | 32:1 | 32:1 | 36:1 | 36:1 | |

Stroke for one input turn [mm] | 1.0 | 1.167 | 1.565 | 1.5 | 1.5 | 1.69 | 1.87 | 1.92 | 2.083 |

0.250 | 0.292 | 0.5 | 0.5 | 0.5 | 0.56 | 0.625 | 0.638 | 0.694 | |

Max permissible power[kW] | 1.45 | 2.59 | 3.47 | 4.02 | 5.38 | 13.06 | 13.9 | 28.5 | 62 |

Weight per 100mm screw & protective tube [kg] | 0.45 | 0.82 | 1.67 | 2.15 | 4.15 | 5.20 | 7.45 | 13.6 | 17.3 |

How to Choose a Screw Jack? Some questions you need answer pls.

Q1: The capacity is to load ? KG (it means how many Kg or Tons the screw jack need to lift or drop?)

The stroke is ? mm (it means the screw shaft length, such as 500mm)

The lifting speed is ? mm/second (it means how much time you want to use to finish the stroke?

Such as I want to use 20 seconds to finish the 500mm stroke then can come out the speed is 25mm/s )

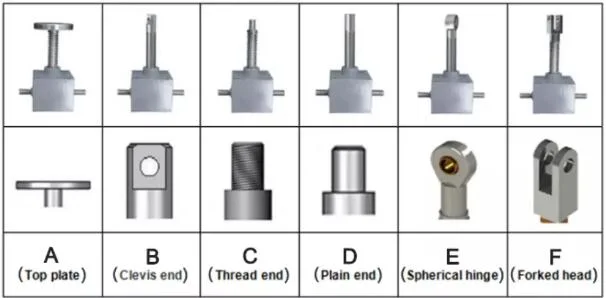

Screw jack SWL2.5-120 performance parameters table as the below: Q2: Which the screw top you need? Answer: I need (A B C D E F).

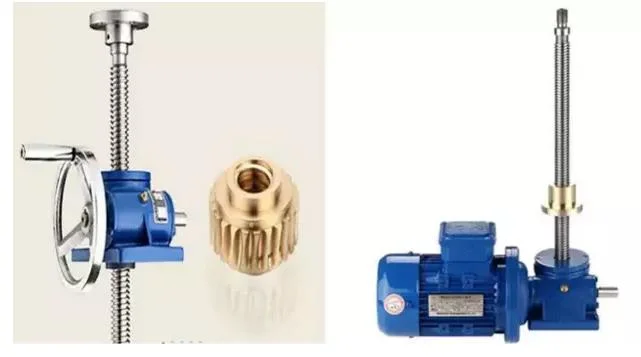

Q2: Which the screw top you need? Answer: I need (A B C D E F). Q3: Manual type (Hand wheel driven) or electric motor driven type? Answer: I need type.

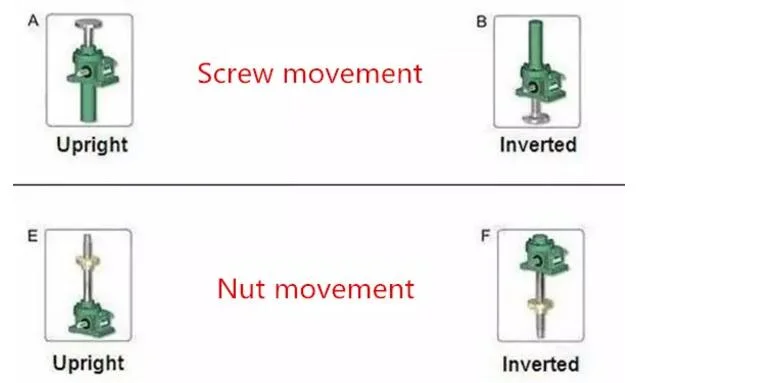

Q3: Manual type (Hand wheel driven) or electric motor driven type? Answer: I need type. Q4: Screw movement (screw travelling up and down when working) or Nut movement (the nut travelling up

Q4: Screw movement (screw travelling up and down when working) or Nut movement (the nut travelling up

and down when working)? Upright or Inverted? Answer: I need (A B E F)

Dawang Transmission Equipment Co., Ltd. located Hangzhou city, Zhejiang, as one professional

manufacturer and exporter of cycloidal pin wheel reducer,worm reducer, gear reducer, gearbox ,

AC motor and relative spare parts, owns rich experience in this line for many years.

We are one direct factory, with advanced production equipment, the strong development team and

producing capacity to offer quality products for customers.

Our products widely served to various industries of Metallurgy, Chemicals, textile,medicine,wooden

etc. Main markets: China, Africa,Australia,Vietnam, Turkey,Japan, Korea, Philippines...

Welcome to ask us any questions, good offer always for you for long term business.

Q: Are you trading company or manufacturer?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock.

Q: Can we buy 1 pc of each item for quality testing?

A: Yes, we are glad to accept trial order for quality testing.

Q:How to choose a gearbox which meets your requirement?

A:You can refer to our catalogue to choose the gearbox or we can help to choose when you provide

the technical information of required output torque, output speed and motor parameter etc.

Q: What information shall we give before placing a purchase order?

A:a) Type of the gearbox, ratio, input and output type, input flange, mounting position, and motor informationetc.

b) Housing color.

c) Purchase quantity.

d) Other special requirements.