mooncake moldmold in a housemetal moldingsplano molding companydie casting moldceramic moldwindshield moldingchair moldingjig moldspaver moldsbumper moldingroto moldinginterior moldingstair nose moldingice pop moldsice ball moldmetal moldstwo shot moldingtwo shot injection molding2 shot injection moldingmulti shot injection moldingdouble shot injection moldingtwo shot moldshot moldtwo shot mouldingtwo shot molding processmulti shot molding2 shot mouldingdual shot injection molding2 shot molding processtwo shot injection mouldingtwin shot mouldingcustom plasticscustom injection molded plasticscustom moldedcustom plastic injectioncustom injection molding costcustom plastic molding costinjection moulding pvcchina plastic moldingplastic injection chinaplastic moulding chinamicro moldingmicro mouldingmicro moldmicro molding incmicro mold plasticsmold componentsplastic injection componentsmoulded componentstwo component injection moldingmulti component injection molding2 component injection mouldinginjection molding polypropyleneinjection molded polypropylenepolypropylene injection mouldingcustom plastic partsplastic part design for injection moldingmolded plastic partsmolding plastic parts at homehow to mold plastic partsinjection moulding advantagesdisadvantages of injection mouldinginjection moulding wikiinjection mould companyhow does injection moulding workinjection moulding advantages and disadvantagespolymer injection mouldinginjection moulding videohow injection moulding worksabout injection mouldingwhat is injection moulding used forinjection moulding disadvantagesthe injection moulding processinjection moulding incchina injection mouldinjection moulding step by stepinjection moulding examplesinjection moulding technologyinjection moulding materialexamples of injection mouldinginjection mould processused injection mouldinginjection moulding technology studentmetal injection moulding ukprocess injection mouldinginjection moulding youtubeinjection moulding processesmaterials used in injection mouldingalternatives to injection mouldinginjection moulding abstwo colour injection mouldingplastik injection mouldinginjection moulding tool designinjection moulding materials usedinjection moulding applicationsinjection moulding techniqueswhy is injection moulding usednylon injection mouldingdemag injection moulding

What We Do For You:

------------------------------------------------------------------------------------------------------------------------------------------------------

Welcome to Prototype & Machining & Mold & Casting Production Company

A single source, providing rapid prototype, CNC machining for samples & production parts, export tooling/ Mold, plactic injection molded & metal casted based products, assembies and parts. Starting with the customers' product, parts, or assembly design, through providing quality and customer service oriented production.

We are from HC-Mold Team in China, thanks for let us to share with you a short overview of our activities:

1. Rapid Prototype Service

CNC Machining, SLA(Stereolithography) and SLS(Selective Laser Sintering), 4~7days lead time.

2. CNC machining Service.

Specialized in CNC turning, 4-axis CNC milling, 5-axis CNC machining, and complex CNC turning&milling

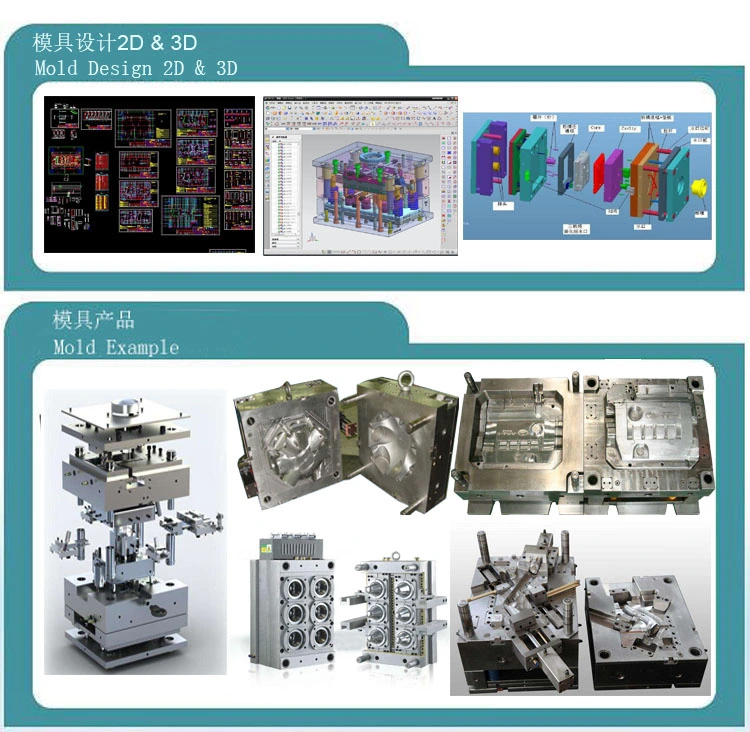

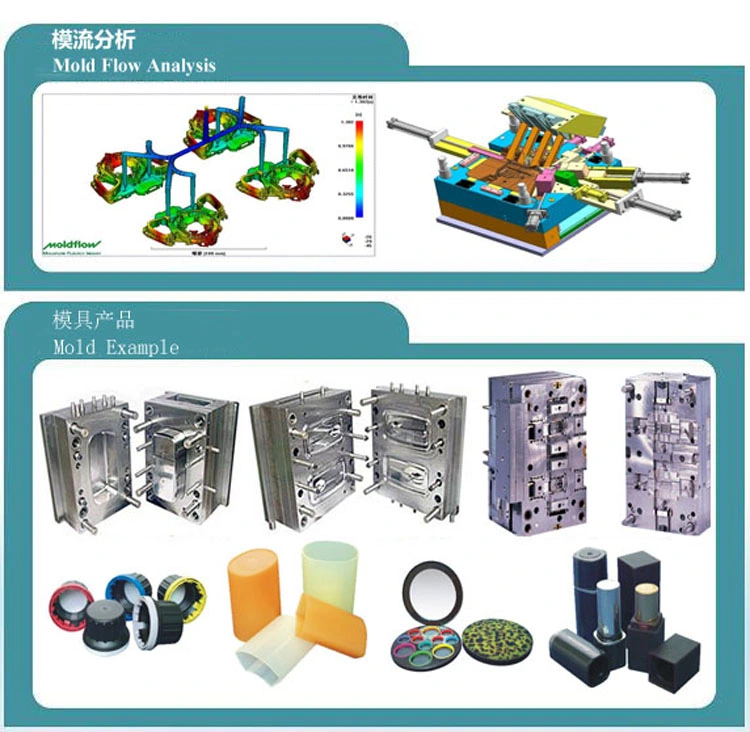

3. Mold Making Service.

We export Molds for problem-free use, and also make economical molds for use in China-we also have the injection machines for molding production.

4. Parts Production, Final Assembly and Packaging service.

To further reduce your cost we produce plastic and metal parts in China further. Assembly is generally the most labor intensive step in the production process, so this is really where we can save you 30% cost.

General Feacture:

------------------------------------------------------------------------------------------------------------------------------------------------------

Let's work together to make your designed-part life come from here...

we offer molds for export , also tooling and molding production in China, either service is optional for you.

mold design and making tooling for export to oversea,

industry tooling for production in China

also mass production including surface treatment and assembly, package in our workshop...

1. Manufacturing Range: from tooling to final production run ...

2. Material: Thermoplastics,Composites, Elastomer, Thermosets...

3.Lead-Time: 2~4 weeks for tooing, and 2 weeks for mass injection production.

4.Tolerance: 0.02mm

5.Quality Management: ISO 9001:2008 and TUV SUD

6.Advantage: High quality, low prices, fast turnaround,

Can form complex shapes and fine details

Excellent surrface finish

Good dimensional accuracy

High production rate

Low labor cost

Scrap can be recycled

7.Application: Housings, Medical equipment , containers, caps, fittings, Household appliances , kitchenware, transportation tool , digital & telecommunication products, toys, custom produc ts, auto parts , etc

The following advantages in mold making and parts production:

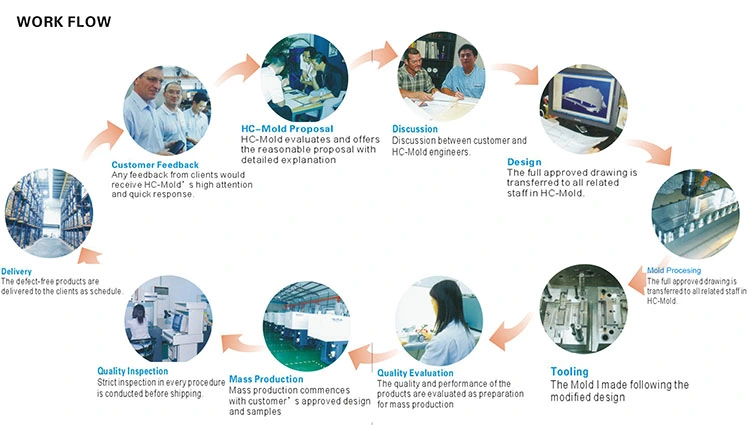

- Perfect Communication - you don't need a mold of the wrong version of your drawings, we have a wide experience working to European standards like DME and Hasco

- Quality Mold Design - design is not always the strongest point of HC-Mold, so our engineers always make sure to design this

- Quality Steel - our QC check and then arrange Purchasing Department to buy the steel ourselves accordingly and then to processes in mold workshops, to make absolutely sure you get the grade you pay for.

- Our Test shot samples are Real - not samples that have been "cleaned up" by hand, we know in Europe you probably don't have 4 girls sitting next to every injection machine

- Reliable lead-times - We send you a progress update with pictures every 2 weeks, and a movie of the test shots

- A Reliable Western Business Partner - we never give up until the molds meet the quality you need

Specification:

------------------------------------------------------------------------------------------------------------------------------------------------------Friendly Note: except the material listed in bellow, we can also support to source the customized material. Thanks!

Let's get your designed-parts life come from here together please!

Molding Material Selection:

Thermoplastics,Composites, Elastomer, Thermosets

for examples: PS,HIPS,ABS,POM,PE,PP,PVC,PC,PA,Nylon PA66,PA+GF, PMMA,

PB, PE-RT, PVC-U(UPVC), HDPE, PP-R, FRPP,LDPE,PTFE(F4),EPDM,XPS,NBR,HIP,PVF,NFPP-R,POF,CPS,PNBR,FEP,PPH,PVDF,PA,RPP,PES,PAM,CPVC, PPB, PS.PEX,PO,CTFE,PMVE,PEVE,PPVE,POVE,PFA,PET,OPP,CPP,POM,MLLDPE,ACM,CR,FPM,HTBN, MQ,CSM,S-BR,NR.ect

| Mold Usage: | 1. rapid expreience tooling 2. export industrial tooling for oversea 3. tooling used in China for future production |

| Mold life: | short such as 50000cycles long, such as 800,000cycles |

| Mold Cavity: | 1.family mold 1+1+1... 2. sigle 1 3. mult-cavity |

| Mold Material: | 618,718,S136/S136H,8407,8402,GS-312,GS-318,GS-738,GS-711,P20M,GS-316,GS-083/083H,GS-344EFS,GS-638,GS-2311,GS-2312,GS-2316,GS-2083/2083H,GS-2344,2311,318,2316/2316H,2344,CLC 2738,CLC 2316H,SP300,738,HP-1A,HP-4A,HP-4MA,HAM-10,HEMS-1A,STD-61,HDS-1,A2,D2,D3,DC11,DC53,DF-2,DF-3,GOA,GSW-2 3 7,9,K100,K110,K460,M2,O1,O2,P18,STD11,XW-10,XW-42,YK30,8407,DH21,DH2F,DH31S,DH42,GSW-2 3 4 4,H10,H11,H13,H21,HDS-1,QRO-90,,STD61,W302,420SS,440C,618,716,718,CLC2083,CLC2316H,CLC2738,CLC2 7 3 8 HH,G-STAR,GSW-2 0 8 3,GSW-2 3 11,GSW-2 3 1 6,GSW-2 7 3 8,HAM-10,HEMS-1A,HP-1A,HP-4A,HP-4MA,M202,M238,M300,M310,NAK55,NAK80,P20,PXZ,PX4,PX5,S45CS50CS55C,S-136,S-STAR,SP300,HFH-1,STF-4M,NAK55,NAK80,PDS-5,PX4,PX5,PX88,PXZ,S-STAR,G-STAR,PAK90,DH2F,GSW-2311,PM-311,GSW-2738,PM-738,GSW-2316,PM-316,GSW-2344,2322,2328,2378,2738,2083,2083ESR,2316,2316ESR,2344,M202,M238,M300,M310/310H,W302,CSM-2,MUP,S45C,S50C,S55C,SKD12,SKD11,SKD1,SKD11,DC11,SKS3,SKS3,SKH9,SKS3,SKH2,SKD11,SKD12,SKS93,SKD61,SKD6,SKD61,SKD5,SUS440C,SUS420J1,1.233,X38C13 |

| Mold Standard: | LKM, DME,HASCO. etc. |

| Molding Production | Yes |

| Seondary Process | Yes, such as surface treatment, assembly, package... |

Tooling and Production Specifications:

| Product Name: | GPPS Mold Maker Plastic Mould 2 Component Injection Moulding Injection Molding Polypropylene Multi Component Injection Molding |

| Key Description | mooncake moldmold in a housemetal moldingsplano molding companydie casting moldceramic moldwindshield moldingchair moldingjig moldspaver moldsbumper moldingroto moldinginterior moldingstair nose moldingice pop moldsice ball moldmetal moldstwo shot moldingtwo shot injection molding2 shot injection moldingmulti shot injection moldingdouble shot injection moldingtwo shot moldshot moldtwo shot mouldingtwo shot molding processmulti shot molding2 shot mouldingdual shot injection molding2 shot molding processtwo shot injection mouldingtwin shot mouldingcustom plasticscustom injection molded plasticscustom moldedcustom plastic injectioncustom injection molding costcustom plastic molding costinjection moulding pvcchina plastic moldingplastic injection chinaplastic moulding chinamicro moldingmicro mouldingmicro moldmicro molding incmicro mold plasticsmold componentsplastic injection componentsmoulded componentstwo component injection moldingmulti component injection molding2 component injection mouldinginjection molding polypropyleneinjection molded polypropylenepolypropylene injection mouldingcustom plastic partsplastic part design for injection moldingmolded plastic partsmolding plastic parts at homehow to mold plastic partsinjection moulding advantagesdisadvantages of injection mouldinginjection moulding wikiinjection mould companyhow does injection moulding workinjection moulding advantages and disadvantagespolymer injection mouldinginjection moulding videohow injection moulding worksabout injection mouldingwhat is injection moulding used forinjection moulding disadvantagesthe injection moulding processinjection moulding incchina injection mouldinjection moulding step by stepinjection moulding examplesinjection moulding technologyinjection moulding materialexamples of injection mouldinginjection mould processused injection mouldinginjection moulding technology studentmetal injection moulding ukprocess injection mouldinginjection moulding youtubeinjection moulding processesmaterials used in injection mouldingalternatives to injection mouldinginjection moulding abstwo colour injection mouldingplastik injection mouldinginjection moulding tool designinjection moulding materials usedinjection moulding applicationsinjection moulding techniqueswhy is injection moulding usednylon injection mouldingdemag injection moulding |

| General Capabilities : | mold design, |

| Industry Focus : | Aerospace Agricultural Architectural Auto/Truck/Transportation Dental Electronic Food Processing Marine Medical Military Natural gas Packaging/Converting |

| Quality: | ISO 9001:2000 |

| Precision: | 0.005mm |

| Mold Runner : | Cold, hot runner such as YUDO.MASTER.SYNVENTIVE.etc. |

| Molding Part Color : | transparent, solid color according to client's requests |

| Mold Surface: | heat treatment, Sandblasting, texture, polishing, EDM.ect |

| Parts Surface : | Screw insert molding, engraving, painting silk printing, Electroplating, spary, printing, UV coating,water transfer, assembly, package. ect textured,glossy or mirror polished,printing,plantingect. |

| Lead time to T1 sample: | 2~5 weeks |

| lead-time for production: | 1~2 weeks |

| Equipment Capabilities : | 80T ~ 1500T injection molding machines for production. proper for differenr part sizes. |

| Secondary Services Offered: | Assembly, Package. |

| Production Volume : | Prototype , Low Volume , Mid Volume , Short Run , Long Run |

| File Formats : | STEP, IGES, SAT, DWG, DXF, VDA, Autodesk Inventor, SolidWorks, CATIA V5, Solid Edge, UGS NX, Pro/ENGINEER |

| Material data: | yes |

| Quality Checking Report | yes |

| Assembly Test | yes |

Casting Projects:

------------------------------------------------------------------------------------------------------------------------------------------------------

HC-Mold is a professional manufacturer for custom plastic injection parts , with a wide range of materials suited to different industries and specialize in both short to mass productions and prototypes .

mooncake moldmold in a housemetal moldingsplano molding companydie casting moldceramic moldwindshield moldingchair moldingjig moldspaver moldsbumper moldingroto moldinginterior moldingstair nose moldingice pop moldsice ball moldmetal moldstwo shot moldingtwo shot injection molding2 shot injection moldingmulti shot injection moldingdouble shot injection moldingtwo shot moldshot moldtwo shot mouldingtwo shot molding processmulti shot molding2 shot mouldingdual shot injection molding2 shot molding processtwo shot injection mouldingtwin shot mouldingcustom plasticscustom injection molded plasticscustom moldedcustom plastic injectioncustom injection molding costcustom plastic molding costinjection moulding pvcchina plastic moldingplastic injection chinaplastic moulding chinamicro moldingmicro mouldingmicro moldmicro molding incmicro mold plasticsmold componentsplastic injection componentsmoulded componentstwo component injection moldingmulti component injection molding2 component injection mouldinginjection molding polypropyleneinjection molded polypropylenepolypropylene injection mouldingcustom plastic partsplastic part design for injection moldingmolded plastic partsmolding plastic parts at homehow to mold plastic partsinjection moulding advantagesdisadvantages of injection mouldinginjection moulding wikiinjection mould companyhow does injection moulding workinjection moulding advantages and disadvantagespolymer injection mouldinginjection moulding videohow injection moulding worksabout injection mouldingwhat is injection moulding used forinjection moulding disadvantagesthe injection moulding processinjection moulding incchina injection mouldinjection moulding step by stepinjection moulding examplesinjection moulding technologyinjection moulding materialexamples of injection mouldinginjection mould processused injection mouldinginjection moulding technology studentmetal injection moulding ukprocess injection mouldinginjection moulding youtubeinjection moulding processesmaterials used in injection mouldingalternatives to injection mouldinginjection moulding abstwo colour injection mouldingplastik injection mouldinginjection moulding tool designinjection moulding materials usedinjection moulding applicationsinjection moulding techniqueswhy is injection moulding usednylon injection mouldingdemag injection moulding

Our Capablity and Quality Management:

------------------------------------------------------------------------------------------------------------------------------------------------------

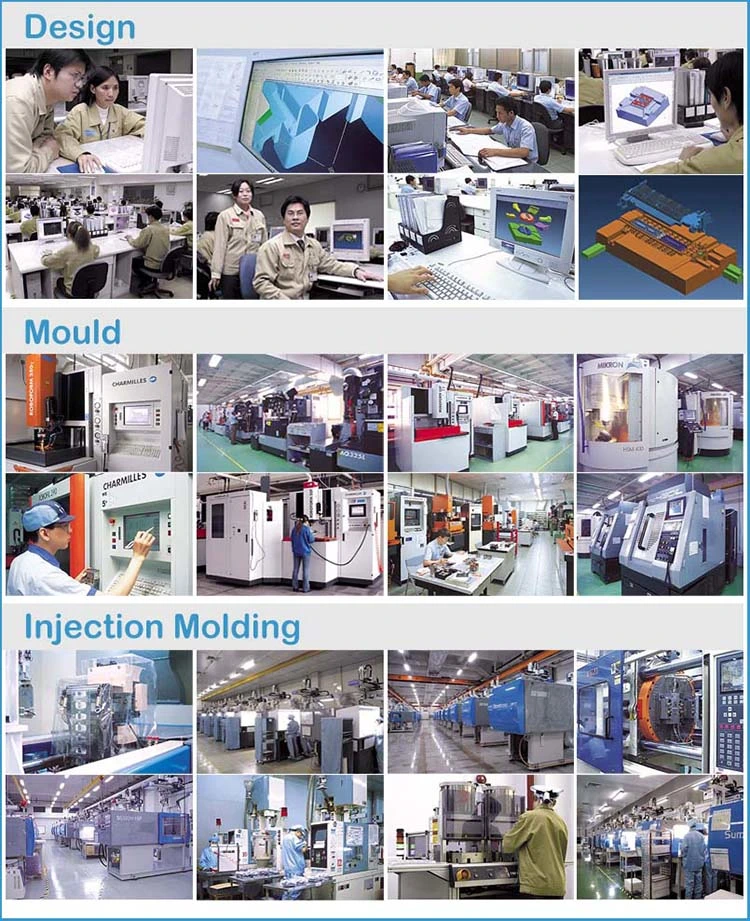

HC-Mold is a professional manufacturer specializing in development, design, manufacture of rapid prototype , CNC machined parts, injection mould , Injection molding production products, as well as finished products assembly which application for Household appliances, kitchenware, transportation tool, digital & telecommunication products, toys, custom products, auto parts, etc

Factory View:

Factory Workshops:

we arrange the prototype making accordingly to ISO system, and control the precision exactly, from raw material, dimensions and surface treatments. also assembly and package too.

Quality Check:

from raw material to final shipment, in each step, we will check the processing during making. also prepare the checking report to clients for approve before each shipment.

Working Flow To Realize Your Prototype and Future Production:

Confidentiality is very important at HC-Mold , we make our quotes internally, so your files will not leave our company, Protection of clients' intellectual property has always had a high priority at HC-Mold.

Instruction of Other Capality (Rapid Prototype and CNC Machining) :

------------------------------------------------------------------------------------------------------------------------------------------------------

Rapid Prototype and CNC machining:

Working with us means you will have physical prototypes back within days. Whether you need CNC, SLA, SLS, FDM or Urethanes, we're proud of our ability to have detailed quotes back to our clients within days. Let's get your next project started!

Contact us for a Quotation:

------------------------------------------------------------------------------------------------------------------------------------------------------

Let's work together to make your designed-part life come from here...

please, send your 3D files, 2D or samples to us for prices, we will check and save you at least 30% off.

For Quote, please contact us as bellow:

1. please send message or enquiry to us directly at this page.

2. or to find our email address at our official website automachining.en.made-in-china.com

We look forward to hear from you when you have a new project coming up, and appreciate the chance to prove to you our unique price/quality performance.

Package and Delivery:

------------------------------------------------------------------------------------------------------------------------------------------------------

we ensure 100% safe package. and fast delivery in term door to door within 3 days. various modes of transport, flexible choice...

- by Express, such as DHL, FedEx, UPS or TNT. 3 days arriving your door.

- By air. also a fast way. cheaper than Express

- by sea, cheapest one way than by express and by air.

Buyer Testimonial:

------------------------------------------------------------------------------------------------------------------------------------------------------

- Production Quality has been superb

we have worked with HC-Mold since 2013. the production quality has been seperb with very low efect rate, the team does a greadt job of setting the expectations and regularly exceding them. we are orking with them on 7 different programs now.

- Performaed in the Top 5%

HC-Mold truly performed in the top 5% of all suppliers we've worked with...they can be trusted to deliver excellendt work and meet deadlines in a very cost effective manner.

Topic Summary:

------------------------------------------------------------------------------------------------------------------------------------------------------

GPPS Mold Maker Plastic Mould 2 Component Injection Moulding Injection Molding Polypropylene Multi Component Injection Molding

mooncake moldmold in a housemetal moldingsplano molding companydie casting moldceramic moldwindshield moldingchair moldingjig moldspaver moldsbumper moldingroto moldinginterior moldingstair nose moldingice pop moldsice ball moldmetal moldstwo shot moldingtwo shot injection molding2 shot injection moldingmulti shot injection moldingdouble shot injection moldingtwo shot moldshot moldtwo shot mouldingtwo shot molding processmulti shot molding2 shot mouldingdual shot injection molding2 shot molding processtwo shot injection mouldingtwin shot mouldingcustom plasticscustom injection molded plasticscustom moldedcustom plastic injectioncustom injection molding costcustom plastic molding costinjection moulding pvcchina plastic moldingplastic injection chinaplastic moulding chinamicro moldingmicro mouldingmicro moldmicro molding incmicro mold plasticsmold componentsplastic injection componentsmoulded componentstwo component injection moldingmulti component injection molding2 component injection mouldinginjection molding polypropyleneinjection molded polypropylenepolypropylene injection mouldingcustom plastic partsplastic part design for injection moldingmolded plastic partsmolding plastic parts at homehow to mold plastic partsinjection moulding advantagesdisadvantages of injection mouldinginjection moulding wikiinjection mould companyhow does injection moulding workinjection moulding advantages and disadvantagespolymer injection mouldinginjection moulding videohow injection moulding worksabout injection mouldingwhat is injection moulding used forinjection moulding disadvantagesthe injection moulding processinjection moulding incchina injection mouldinjection moulding step by stepinjection moulding examplesinjection moulding technologyinjection moulding materialexamples of injection mouldinginjection mould processused injection mouldinginjection moulding technology studentmetal injection moulding ukprocess injection mouldinginjection moulding youtubeinjection moulding processesmaterials used in injection mouldingalternatives to injection mouldinginjection moulding abstwo colour injection mouldingplastik injection mouldinginjection moulding tool designinjection moulding materials usedinjection moulding applicationsinjection moulding techniqueswhy is injection moulding usednylon injection mouldingdemag injection moulding